AISI 4140 SCM440 DIN 42CrMo4 1.7225 Alloy Steel gburugburu Bar

Nkọwa ngwaahịa

A na-akọwa AISI 4140 dị ka obere alloy alloy nke nwere 1% Cr-Mo dị ka ihe na-eme ka ihe ndị na-eme ka ihe dị ike. E jiri ya tụnyere AISI 4130, ọ nwere ọdịnaya carbon dị elu na nguzozi dị mma nke ike, ike siri ike, abrasion na mmetụta nkwụsị na ike ọgwụgwọ okpomọkụ, ma. A na-enye AISI 4140 n'ụdị ọnọdụ ike gwụrụ na nke siri ike 28-32HRC.

4140 nwere ike dị elu, ike siri ike, ike siri ike, na nrụrụ n'oge imenyụ.Ọ nwere nnukwu ike na-akpụ akpụ na ike ntachi obi na oke okpomọkụ.A na-eji ya maka imepụta forgings nke chọrọ ike dị elu na akụkụ ndị na-agbanyụ ọkụ na nke dị ọkụ karịa 4135 ígwè, dị ka nnukwu ngwo maka traction locomotive, booster nnyefe gia, azụ axles, njikọ mkpara na mmiri mkpachị na-ebujuru.

Nkọwapụta

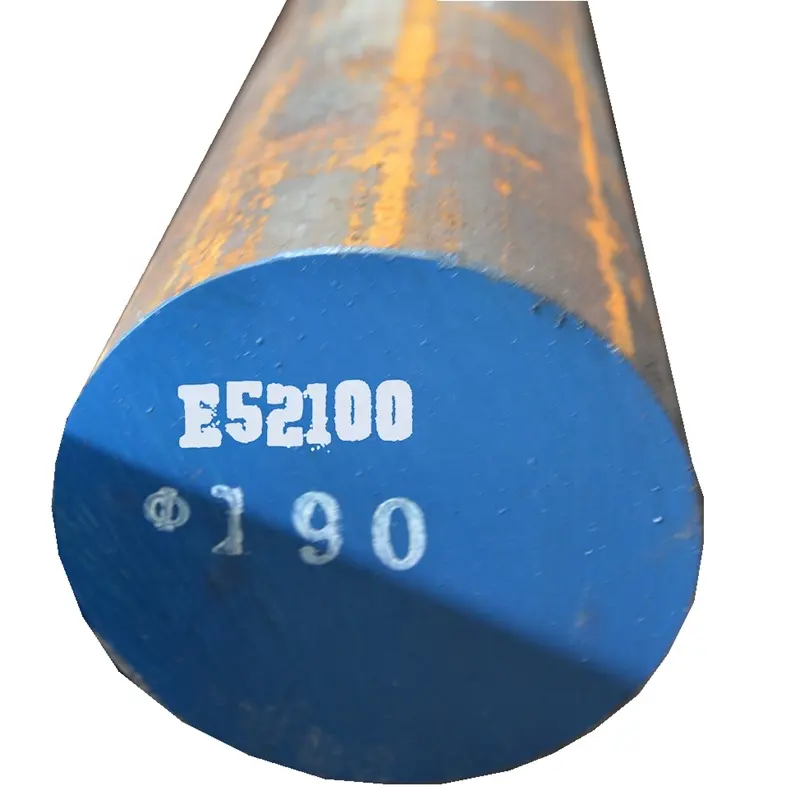

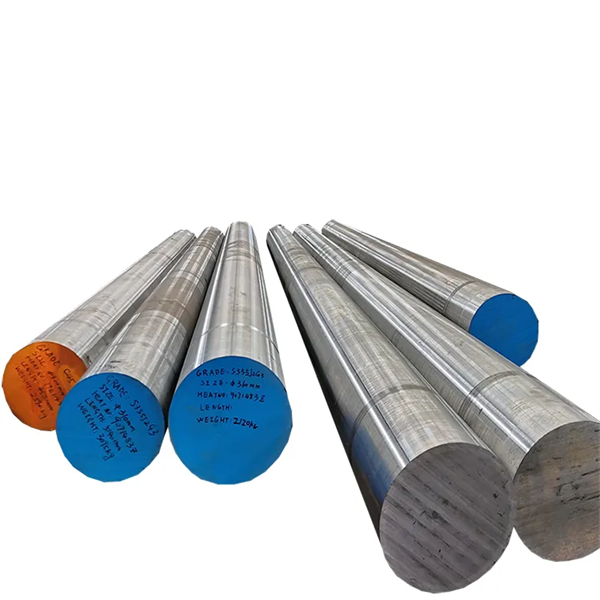

| Aha ngwaahịa | AISI 4140 SCM440 DIN 42CrMo4 1.7225 Alloy Steel gburugburu Bar | |

| Ihe onwunwe | ASTM | 4140 |

| DIN | 42 crmo4 | |

| GB | 42CrMo | |

| Ọkọlọtọ | GB/T799, ASTM A29, A108, A321, A575, BS970, DIN1652, JIS G4051 | |

| OD | 6mm ka 600mm | |

| Elu | Agba oji, Obere, Nchacha, Chrome plated | |

| Nkọwapụta | Ogwe okirikiri | 8mm ~ 800mm |

| Ogwe akụkụ | 3mm * 20mm * 20mm ~ 12mm * 800mm * 800mm | |

| Ogwe square | 4mm * 4mm ~ 100mm * 100mm | |

| Ogwe dị larịị | 2 * 10mm ~ 100 * 500mm | |

| Hexagonal | 4mm ~ 800mm | |

| Ọnọdụ | Ụgha;Hot akpọrepu;Oyi sere | |

| Usoro | Ọkụ eletrik gbazere, akpụkọrọ akpụkọ na annealed, mmanya okirikiri tụgharịa. | |

| Isi ike: | HBS 217Max (dị iche na ọgwụgwọ okpomọkụ)QT 28-32HRC | |

| Ule UT | SEP 1921/84/2 C/c klas. | |

| Ndidi | Dia -0/+ 0 ~ 5mm, Ọkpụrụkpụ -0/+ 0 ~ 5mm, Obosara: -0/+ 0 ~ 10mm. | |

| Ogologo | 2m,4m,5.8m,6m,11.8m,12m ma ọ bụ dị ka achọrọ. | |

| ngwugwu | Nkwakọ ngwaahịa kwesịrị ekwesị. | |

AISI 4140 nha ọkwa ọkwa

| Obodo | China | Japan | Germany | USA | British |

| Ọkọlọtọ | GB/T 3077 | JIS G4105 | DIN (W-Nr.) EN 10250 | AISI/ASTM ASTM A29 | BS 970 |

| Ọkwa | 42CrMo | SCM440 | 42crmo4/1.7225 | 4140 | EN19/709M40 |

AISI 4140 ígwè chemical mejupụtara (%)

| Ọkwa | C | Si | Mn | P | S | Cr | Mo |

| 42CrMo | 0.38-0.45 | 0.17-0.37 | 0.5-0.80 | ≤0.035 | ≤0.035 | 0.9-1.2 | 0.15-0.25 |

| SCM440 | 0.38-0.43 | 0.15-0.35 | 0.6-0.85 | ≤0.035 | ≤0.04 | 0.9-1.2 | 0.15-0.30 |

| 42crmo4/1.7225 | 0.38-0.45 | ≤ 0.4 | 0.6-0.9 | ≤0.025 | ≤0.035 | 0.9-1.2 | 0.15-0.30 |

| 4140 | 0.38-0.43 | 0.15-0.35 | 0.75-1.00 | ≤0.035 | ≤0.04 | 0.8-1.1 | 0.15-0.25 |

| EN19/709M40 | 0.35-0.45 | 0.15-0.35 | 0.5-0.80 | ≤0.035 | ≤0.035 | 0.9-1.5 | 0.2-0.40 |

AISI 4140 ígwè ígwè arụ ọrụ

| Ọkwa | Ịkwụsị ike σb (MPa) | Mmụba ike σs (MPa) | Ogologo oge 5 (%) | Mbelata ψ (%) | Mmetụta Uru Akv (J) | Isi ike |

| 4140 | ≥1080 | ≥930 | ≥12 | ≥45 | ≥63 | 28-32HRC |

Ngwa

AISI 4140 steel na-achọta ọtụtụ ngwa dị ka forgings maka ikuku, mmanụ na gas, ụgbọ ala, ọrụ ugbo na ụlọ ọrụ nchekwa wdg. Ngwa a na-ahụkarị maka 4140 ígwè eji eme ihe gụnyere: ngwa ngwa, spindles, fixtures, jigs, collars, Axles,conveyor parts, Crow Bars akụkụ osisi, aro, sprockets, studs, pinions, mgbapụta aro, ebule, na mgbanaka gia wdg.

Ntụkwasị obi ịdị mma

1. Kwụsie ike dị ka achọrọ

2. Nlereanya: Nlereanya dị.

3. Nnwale: Nnwale ịgba nnu nnu / ule tensile / Eddy current / Chemical mejupụtara ule dị ka arịrịọ ndị ahịa si dị.

4.Certificate: IATF16949, ISO9001, SGS wdg.

5. EN 10204 3.1 Asambodo