AISI SAE 4130 4140 4145H Steel Round Bar oghere oghere

Atụmatụ

4130 4135 4140 4145H ígwè ogwe bụ obere carbon alloy ígwè.Ha bụ nke Chrome-Molly alloy nke nwere chromium na molybdenum dị ka ihe na-ewusi ike.

Ogwe ígwè 4130 gburugburu nwere ikike ọrụ dị mma, nrụrụ nhazi pere mpe, yana nguzogide ike ọgwụgwụ dị mma.Ọ bụ nke udi nke ọkara ruo elu ike ike ígwè.Mgbe ọgwụgwọ okpomọkụ gasịrị, 4140 nwere ike dị mma na akụrụngwa akụrụngwa zuru oke, ikike usoro dị mma, na mkpụrụ dị elu.Okpomọkụ ọrụ bụ 427 Celsius.

4140 nwere ike dị elu, ike siri ike, ike siri ike, na nrụrụ n'oge imenyụ.Ọ nwere nnukwu ike na-akpụ akpụ na ike ntachi obi na oke okpomọkụ.A na-eji ya maka imepụta forgings nke chọrọ ike dị elu na akụkụ ndị na-agbanyụ ọkụ na nke dị ọkụ karịa 4135 ígwè, dị ka nnukwu ngwo maka traction locomotive, booster nnyefe gia, azụ axles, njikọ mkpara na mmiri mkpachị na-oke ibu.

Nkọwapụta

| Aha ngwaahịa | AISI ASTM 4130 4135 4140 Alloy Steel Bar | |

| Ihe onwunwe | ASTM | 4130,4135 4140,4145H |

| DIN | 1.7218 1.7225 1.7220 | |

| GB | 30CrMo 35CrMO 42CrMo | |

| Ọkọlọtọ | GB/T799, ASTM A29, A108, A321, A575, BS970, DIN1652, JIS G4051 | |

| OD | 6mm ka 600mm | |

| Elu | Agba oji, Obere, Nchacha, Chrome plated | |

| Nkọwapụta | Ogwe okirikiri | 8mm ~ 800mm |

| Ogwe akụkụ | 3mm * 20mm * 20mm ~ 12mm * 800mm * 800mm | |

| Ogwe square | 4mm * 4mm ~ 100mm * 100mm | |

| Ogwe dị larịị | 2 * 10mm ~ 100 * 500mm | |

| Hexagonal | 4mm ~ 800mm | |

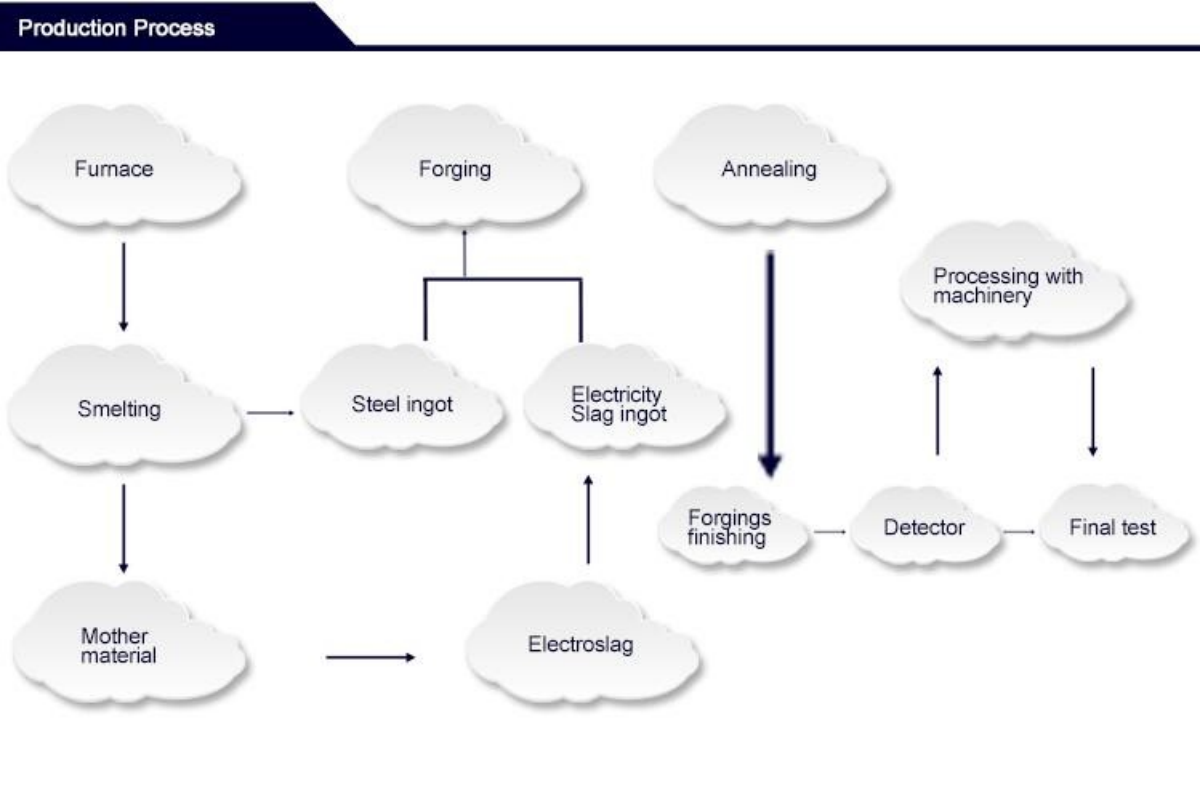

| Usoro | Ọkụ eletrik gbazere, akpụkọrọ akpụkọ na annealed, mmanya okirikiri tụgharịa. | |

| Isi ike: | HBS 217Max (dị iche na ọgwụgwọ okpomọkụ) | |

| Ule UT | SEP 1921/84/2 C/c klas. | |

| Ndidi | Dia -0/+ 0 ~ 5mm, Ọkpụrụkpụ -0/+ 0 ~ 5mm, Obosara: -0/+ 0 ~ 10mm. | |

| Ogologo | 2m,4m,5.8m,6m,11.8m,12m ma ọ bụ dị ka achọrọ. | |

| ngwugwu | Nkwakọ ngwaahịa kwesịrị ekwesị. | |

| Ha nhata ọkọlọtọ dị iche iche | |||

| AISI | GB | DIN | JIS |

| 4130 | 30CrMo | 1.7218 | SCM420 |

| 4140 | 42CrMo | 1.7225 (42CrMo4) | SCM440 |

| 4135 | 35Crmo | 1.7220 (34CrMo4) | SCM432 |

| 4145H | - | - | - |

Ngwakọta kemịkalụ

| Ngwakọta kemịkalụ (%) | |||||||

| Ọkwa | C | Si | Mn | P | S | Cr | Mo |

| 4130 | 0.28-0.33 | 0.15-0.35 | 0.40-0.60 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4140 | 0.38-0.43 | 0.15-0.35 | 0.75-1.0 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4135 | 0.33-0.38 | 0.15-0.35 | 0.75-0.9 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4145 | 0.43-0.48 | 0.15-0.35 | 0.75-1.0 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

Ihe eji arụ ọrụ

| Njirimara: |

| 1.Low alloy ígwè nwere molybdenum na chromium dị ka ndị na-ewusi ike; |

| 2.Excellent si fusion weldability ele anya; |

| 3.The alloy nwere ike sie ike site na ọgwụgwọ okpomọkụ. |

Ndidi

| Ọnọdụ nnyefe |

| 1. Hot akpọrepu |

| 2.Annealed |

| 3.Normalized |

| 4. Wepụ na iwe |

Ọnọdụ ọgwụgwọ okpomọkụ

1.Annealing: 880 ℃ ọkụ jụrụ oyi

2.Normalisation: 880 ~ 870 ℃ ikuku jụrụ oyi

3.Hardening: 820 ~ 870 ℃ Mmiri jụrụ oyi

4.Tempering: 550 ~ 650 ℃ ngwa ngwa jụrụ oyi

Enwere ike nweta ihe eji arụ ọrụ site na ọgwụgwọ okpomọkụ dị iche iche.

ngwugwu

1.By bundles, onye ọ bụla ngwugwu arọ n'okpuru 3 tọn, maka obere mpụta

dayameta gburugburu mmanya, nke ọ bụla ùkwù nwere 4 - 8 ígwè ibe.

2.20 ụkwụ akpa nwere akụkụ, ogologo n'okpuru 6000mm

3.40 ụkwụ akpa nwere akụkụ, ogologo n'okpuru 12000mm

4.By nnukwu arịa, ụgwọ ibu dị ala site na nnukwu ibu, na nnukwu

Enweghị ike ibuba nha dị arọ n'ime arịa nwere ike ibupu site na nnukwu ibu

Ntụkwasị obi ịdị mma

1.Strict dị ka achọrọ

2. Nlereanya: Nlereanya dị.

3. Nnwale: Nnwale ịgba nnu nnu / ule tensile / Eddy current / Chemical mejupụtara ule dị ka arịrịọ ndị ahịa si dị.

4.Certificate: IATF16949, ISO9001, SGS wdg.

5. EN 10204 3.1 Asambodo