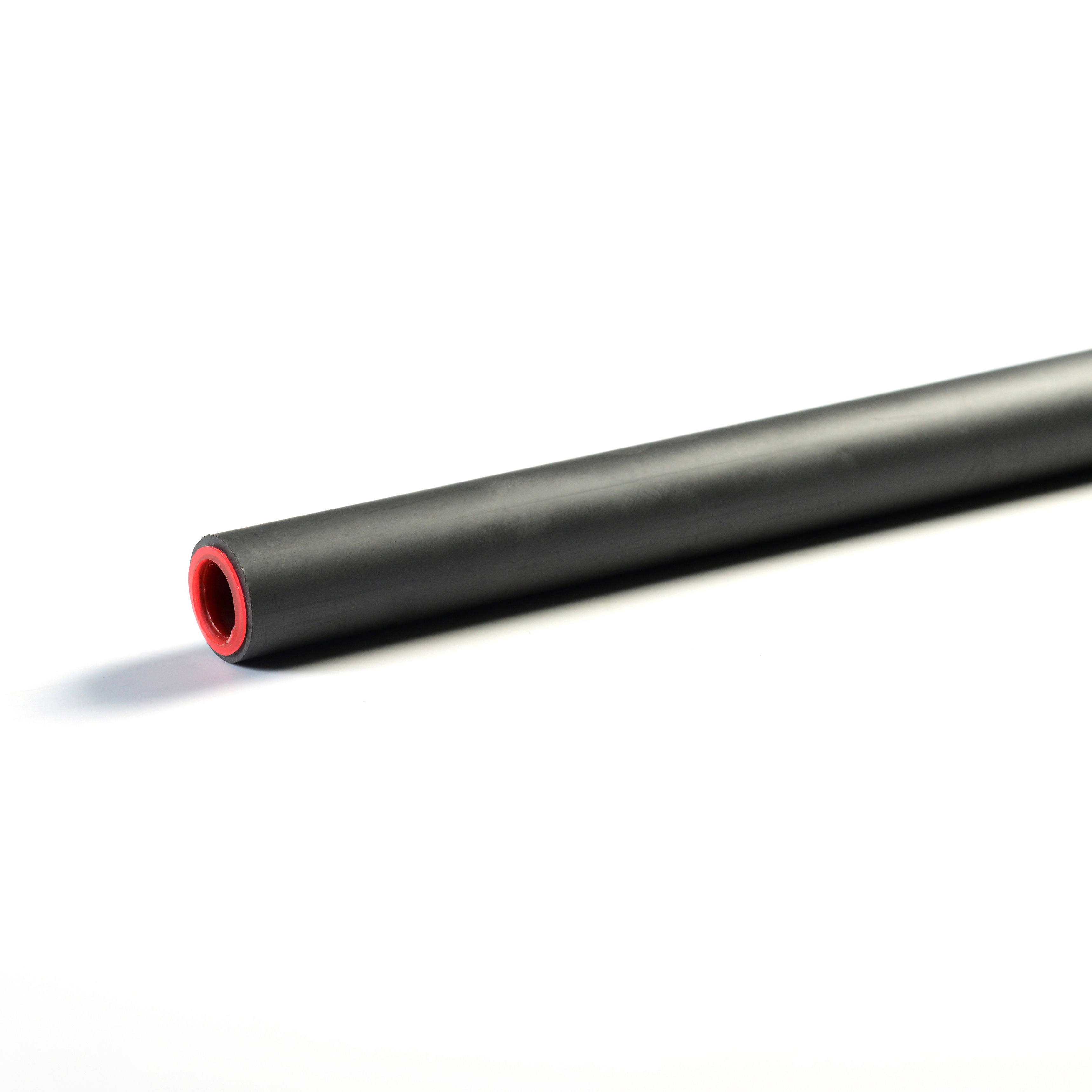

phosphat ziri eziedọkpọkọbụ ụdị ọkpọkọ ọhụrụ nke na-eguzogide iyi, nke na-eji usoro ihe mejupụtara ọnụ ọnụ nke na-agba agba.Ọ na-guzobere site n'ibu ọrụ nke spinning nesting mejupụtara abụọ dị iche iche akụrụngwa metal ihe ọnụ, na nkà mmụta sayensị tinye n'ọrụ na mpụga isi ọkpọkọ mgbidi ọkpụrụkpụ na-ebu ọrụ nrụgide nke pipeline usoro, na-eji lined corrosion na-eguzogide alloy ọkpọkọ na-ebu. corrosion chọrọ nke usoro pipeline.

E jiri ya tụnyere ígwè nkedo alloy na-eguzogide iyi nke ọdịnala, ihe nkedo alloy na-eguzogide iyi, ọkpọkọ seramiiki mejupụtara ọkpọkọ, na ọkpọkọ nkume, phosphat nkenke a.ed ọkpọkọ nwere uru ndị a.

1. Ezi mgbochi iyi.

2. Nguzogide nrụgide dị elu, kwesịrị ekwesị maka ọkwa nrụgide dị elu.

3. A na-ejikọta ihe mkpuchi nke dị n'ime ya na ọkpọkọ ígwè dị n'èzí, a na-ahọrọ usoro pụrụ iche iji mepụta njikọ njikọ n'etiti ngwakọta ihe mejupụtara, na-eme ka ntụkwasị obi rụọ ọrụ.

4. Ọ nwere ezigbo iguzogide ujo igwe na ujo thermal.

5. Njikọ ngwaọrụ dị mma.Enwere ike iji flanges na nkwonkwo na-agbanwe agbanwe maka njikọ, enwere ike ịkpụ ma ọ bụ welded na ọchịchọ.

Oke ojiji:

Sistemụ ebufe coal ntụ ntụ, ọkpọkọ na-ebuga unyi kpọrọ nkụ, na sistem okwute na ụlọ ọrụ ọkụ ọkụ

Sistemụ mbufe pneumatic ndị ọzọ maka irighiri uzuzu

Sistemụ njem ụgbọ njem hydraulic slag na ụgbọ njem slurry nwere oke urughuru buru ibu

Ụgbọ njem nke dị iche iche Ngwuputa ihe

1. Mmetụta phosphating

(1) Mmetụta nke phosphating tupu mkpuchi

① Mee ka adhesion dị n'etiti mkpuchi mkpuchi (dị ka mkpuchi agba) na workpiece.

② Meziwanye nguzogide corrosion nke mkpuchi elu nke workpiece mgbe mkpuchi.

③ Mma mma.

(2) Mmetụta nke enweghị mkpuchi phosphating

① Mma na-eyi nguzogide nke workpiece.

② Gbaa mbọ hụ na ọ dị nro nke workpiece n'oge eji arụ ọrụ.

③ Melite nguzogide corrosion nke workpiece.

2. Ngwa nke phosphating

A na-ejikarị phosphating ígwè eme ihe maka nchebe corrosion yana dịka ihe nkiri ndabere maka agba.

(1) Ihe nkiri phosphating maka nchebe corrosion

① A na-eji ihe nkiri phosphating na-echebe maka ọgwụgwọ nchebe corrosion nke akụkụ ígwè.Ụdị ihe nkiri phosphating nwere ike ịbụ zinc ma ọ bụ manganese.Ọnụ ọgụgụ nke otu akụkụ nke akpụkpọ ahụ bụ 10-40 g/m2.Tinye mmanụ mgbochi nchara, griiz, wax na ihe ndị ọzọ mgbe phosphat gachara.

② Ihe nkiri phosphating maka agba agba

Dịkwuo adhesion na nchebe n'etiti agba film na ígwè workpieces.Ụdị ihe nkiri phosphating nwere ike ịbụ zinc dabeere ma ọ bụ zinc calcium dabeere.Akụkụ mpaghara mpaghara nke ihe nkiri phosphating bụ 0.2-1.0 g / m2 (nke a na-eji maka akwa oyi akwa nke agba na nnukwu akụkụ nchara);1-5 g / m2 (eji maka akwa oyi akwa nke agba na akụkụ nchara n'ozuzu);5-10 g / m2 (n'ihi na agba isi oyi akwa nke nchara akụkụ na-adịghị eme nrụrụ).

(2) Mkpuchi phosphate maka oyi na-arụ ọrụ ire ụtọ

The film arọ kwa unit ebe nke ígwè waya na welded ígwè ọkpọkọ ịbịaru bụ 1-10 g / m2;Ibu ihe nkiri kwa otu mpaghara nke eserese tube phosphating ziri ezi bụ 4-10 g / m2;The film arọ kwa unit ebe oyi extrusion akpụ nke ígwè akụkụ bụ ukwuu karịa 10 g / m2.

(3) Mkpuchi phosphate maka ibelata esemokwu

Ihe nkiri phosphate nwere ike ibelata esemokwu.N'ozuzu, a na-eji phosphating dabeere na manganese, a pụkwara iji phosphating dabeere na zinc.Maka workpieces nwere obere oghere dabara adaba, oke ihe nkiri phosphating bụ 1-3 g / m2;Maka workpieces nwere nnukwu oghere dabara adaba (gearbox gears), oke ihe nkiri phosphating bụ 5-20 g/m2.

(4) Mkpuchi phosphate maka mkpuchi eletriki

N'ozuzu, a na-eji phosphating dabeere na zinc.Ejiri ya maka ọgwụgwọ silicon wafer phosphating na moto na transformers.

Oge nzipu: Ọgọst-24-2023