Comprehensive pickling napassivation nke igwe anaghị agba nchara, na-ewepụ ntụpọ mmanụ dị iche iche, nchara, akpụkpọ anụ oxide, nkwonkwo solder na unyi ndị ọzọ.Mgbe ọgwụgwọ gasịrị, elu ahụ na-acha ọcha na-acha ọcha na-acha ọcha, na-emeziwanye nguzogide corrosion nke igwe anaghị agba nchara, dabara maka akụkụ igwe anaghị agba nchara dị iche iche, efere na akụrụngwa.

Ọ dị mfe iji rụọ ọrụ, dị mfe iji, akụ na ụba na nke bara uru, yana mgbakwunye nke ihe mgbochi corrosion na-arụ ọrụ nke ọma iji gbochie nrụrụ ígwè na embrittlement hydrogen, na igbochi ọgbọ nke alụlụ acid.Karịsịa adabara obere na mgbagwoju anya workpieces, adịghị adabara mkpuchi, elu ka yiri ngwaahịa na ahịa.

Dị ka ịdị arọ nke igwe anaghị agba nchara na ọnụ ọgụgụ oxide si dị, a pụrụ iji ngwọta mbụ mee ihe ma ọ bụ tinye ya na mmiri na nha nke 1: 1: 1-4 tupu ejiri ya;Ferrite, Martensite na austenitic igwe anaghị agba nchara na obere nickel ọdịnaya (dị ka 420.430.200.201.202.300. Mgbe dilution, austenitic igwe anaghị agba nchara na elu nickel ọdịnaya (dị ka 304), 321.316.316L, wdg) ga-nkwadebe;N'ozuzu, mgbe nkịtị okpomọkụ ma ọ bụ kpo oku ka 50 ~ 60 ℃, sook maka 3-20 nkeji ma ọ bụ karịa (kpọmkwem oge na okpomọkụ ga-ekpebisi ike site onye ọrụ dị ka ikpe ọnọdụ) ruo n'elu unyi kpamkpam wepụrụ, evenly silvery ọcha. , na-akpụ a edo na ok passive film.Mgbe ọgwụgwọ gasịrị, wepụ ya, saa ya na mmiri dị ọcha, ma wepụ ya na mmiri alkaline ma ọ bụ limewater.

Mkpa nke igwe anaghị agba nchara pickling na passivation

Igwe anaghị agba nchara nwere ezigbo nguzogide corrosion, nguzogide oxidation dị elu, arụmọrụ dị ala dị ala, yana ezigbo igwe na akụrụngwa R.Ya mere, a na-eji ya na kemịkalụ, mmanụ ala, ike, injinia nuklia, ikuku ikuku, mmiri, ọgwụ, ụlọ ọrụ ọkụ, textile na akụkụ ndị ọzọ.Ebumnuche ya bụ igbochi corrosion na nchara.The corrosion eguzogide nke igwe anaghị agba nchara tumadi dabere na elu passivation film.Ọ bụrụ na ihe nkiri ahụ ezughị oke ma ọ bụ nwee ntụpọ, igwe anaghị agba nchara ka ga-emebi emebi.A na-ejikarị pickling acid na passivation eme ihe na injinịa iji kwalite nguzogide corrosion nke igwe anaghị agba nchara.N'oge e guzobere, mgbakọ, ịgbado ọkụ, weld nnyocha (dị ka flaw nchọpụta, mgbali ule), na-ewu akara usoro nke igwe anaghị agba nchara akụrụngwa na components, n'elu mmanụ stains, nchara, na-abụghị ọla, ala agbaze ebe metal pollutants, agba, ịgbado ọkụ slag, na splashes nwere ike imetụta elu àgwà igwe anaghị agba nchara akụrụngwa na components, mebie oxide film n'elu ha, belata keukwu na mpaghara corrosiveness nke ígwè (gụnyere pitting corrosion), ọdịiche corrosion), na ọbụna na-eduga ná nrụgide corrosion cracking. .

Nhicha elu nke igwe anaghị agba nchara, pickling na passivation nwere ike ọ bụghị naanị melite nguzogide corrosion ruo n'ókè kachasị, kamakwa gbochie mmetọ ngwaahịa ma nweta mmetụta aesthetic.GBl50-1998 "Ụgbọ mmiri nrụgide ígwè" na-ekwu na a ga-achịkọta elu na ihe ndị dị n'elu nke igwe anaghị agba nchara na efere ígwè mejupụtara.Iwu a na-emetụta ụgbọ mmiri nrụgide ejiri na ụlọ ọrụ petrochemical.Dị ka a na-eji ngwá ọrụ ndị a n'ọnọdụ ebe ha na-abata kpọmkwem na mgbasa ozi na-emebi emebi, ọ dị mkpa ịtụ aro pickling acid na passivation site n'echiche nke ịhụ na nguzogide corrosion na corrosion resistance.Maka ụlọ ọrụ mmepụta ihe ndị ọzọ, ọ bụrụ na ọ bụghị maka mgbochi corrosion, ọ na-adabere na ihe ndị a chọrọ nke ịdị ọcha na aesthetics, ebe igwe anaghị agba nchara anaghị achọ pickling na passivation.Ma welds nke igwe anaghị agba nchara na-achọkwa pickling na passivation Maka ụfọdụ ngwa kemịkalụ nwere ihe siri ike chọrọ maka ojiji, na mgbakwunye na nhicha acid na ngafe, a ga-ejikwa ihe dị ọcha dị ọcha mee ihe maka nhicha ikpeazụ ma ọ bụ nhicha ígwè, imecha kemịkalụ na Electropolishing.

Ụkpụrụ nke nchịkọta igwe anaghị agba nchara na ngafe

Nguzogide corrosion nke igwe anaghị agba nchara bụ n'ihi eziokwu ahụ bụ na ekpuchiri elu ya na ihe nkiri passivation dị oke mkpa (ihe dị ka 1) nm, nke na-ekewapụ ihe na-emebi emebi ma na-eje ozi dị ka ihe mgbochi bụ isi maka nchebe igwe anaghị agba nchara.Passivation igwe anaghị agba nchara nwere njirimara dị egwu na e kwesịghị iwere ya dị ka nkwụsị zuru oke nke corrosion.Kama, ekwesịrị ịmepụta oyi akwa mgbochi mgbasa, na-ebelata oke mmeghachi omume anode.Ọtụtụ mgbe, mgbe enwere ihe na-ebelata (dị ka ions chloride), akpụkpọ ahụ na-emebi, na mgbe enwere ihe na-eme ka ikuku oxidizing (dị ka ikuku), enwere ike idobe ma ọ bụ mezie akpụkpọ ahụ.

Igwe anaghị agba nchara workpieces etinye n'ikuku ga-etolite ihe oxide film, ma ha nchebe ezughị.Ọtụtụ mgbe, a na-ebu ụzọ ihicha nke ọma, gụnyere alkaline na ịsacha acid, na-esote passivation na oxidant iji hụ na iguzosi ike n'ezi ihe na nkwụsi ike nke ihe nkiri passivation.Otu n'ime ebumnuche nke pickling bụ ịmepụta ọnọdụ dị mma maka ọgwụgwọ passivation ma hụ na e guzobere ihe nkiri passivation dị elu.Ịsacha acid na-akpata corrosion n'elu igwe anaghị agba nchara nwere nkezi ọkpụrụkpụ nke 10m.Ọrụ kemịkalụ nke ngwọta acid na-eme ka ọnụọgụ mgbasa nke mpaghara ntụpọ dị elu karịa nke akụkụ ndị ọzọ nke elu.Ya mere, ịsacha acid nwere ike ime ka elu ahụ dum guzozie n'ụzọ ziri ezi ma wepụ ụfọdụ ihe egwu mmebi.Mana nke kachasị mkpa, site na pickling acid na passivation, ígwè na ígwè oxides na-agbaze karịa chromium na chromium oxides, na-ewepụ oyi akwa chromium dara ogbenye, na-eme ka chromium bara ụba n'elu igwe anaghị agba nchara.Ike nke ihe nkiri passivation chromium bara ụba nwere ike iru + 1.0V (SCE), nke dị nso na ikike nke ọla dị oke ọnụ ahịa ma na-eme ka nkwụsi ike nke nguzogide corrosion dịkwuo mma.Usoro ọgwụgwọ passivation dị iche iche nwekwara ike imetụta nhazi na nhazi nke ihe nkiri ahụ, si otú ahụ na-emetụta nguzogide corrosion ya.Dịka ọmụmaatụ, site na ọgwụgwọ mgbanwe electrochemical, ihe nkiri passivation nwere ike ịnwe nhazi multi-layer ma mepụta Cro3 ma ọ bụ Cr2O3 n'ime ihe mgbochi mgbochi, ma ọ bụ mepụta ihe nkiri oxide iko iji kwalite nguzogide corrosion nke igwe anaghị agba nchara.

1.Stainless ígwè pickling na passivation usoro

A na-eji usoro impregnation mee ihe maka akụkụ ndị nwere ike itinye na tankị pickling ma ọ bụ passivation, ma ọ dịghị adabara ogologo oge iji ngwọta pickling na nnukwu ngwá ọrụ, na-arụpụta ọrụ dị elu na ọnụ ala dị ala;Ngwá ọrụ dị ukwuu na-ejupụta na ngwọta acid, na oriri mmiri na-emikpu dị oke elu.

Kwesịrị ekwesị maka ime elu na ime ime obodo nke nnukwu akụrụngwa.Ọnọdụ ọrụ na-adịghị mma na enweghị ike ị nwetaghachi ngwọta acid.

A na-eji usoro mado eme ihe na ntinye ma ọ bụ nrụzi saịtị, karịsịa maka ọrụ aka na ngalaba ịgbado ọkụ.Ọnọdụ ọrụ adịghị mma na ọnụ ahịa mmepụta dị elu.

A na-eji usoro ịgbasa na saịtị ntinye, na-enwe obere mmiri mmiri dị n'ime mgbidi nke nnukwu arịa, ọnụ ala dị ala, na ngwa ngwa ngwa ngwa, ma na-achọ nhazi nke egbe ịgbasa na usoro mgbasa ozi.

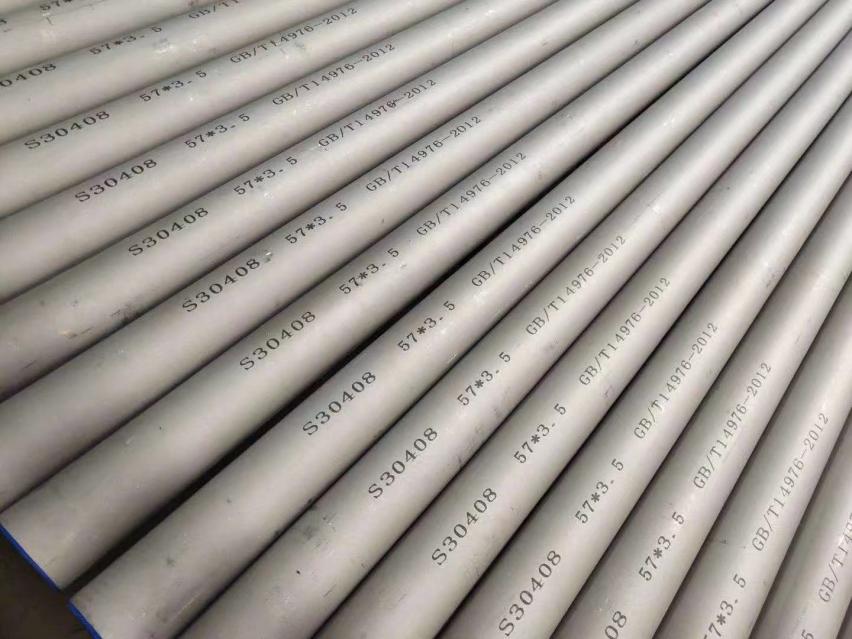

A na-eji usoro mgbasa ozi maka akụrụngwa buru ibu, dị ka ndị na-ekpo ọkụ ọkụ.Owuwu nke tube na ọgwụgwọ shei dị mma, a pụkwara iji ngwọta acid mee ihe ọzọ.Ọ na-achọ ọkpọkọ na mgbapụta njikọ na usoro mgbasa ozi.

Enwere ike iji usoro electrochemical mee ihe maka akụkụ, kamakwa maka ọgwụgwọ elu nke akụrụngwa na saịtị.Teknụzụ dị mgbagwoju anya ma chọọ ọkụ DC ma ọ bụ potentiostat.

2.Pickling na passivation usoro

Iwetu na ihicha unyi → Ịsacha akụkụ nke nchacha mmiri → Passivation → Na-eji mmiri dị ọcha saa → Na-ekpo ọkụ

3.Pretreatment tupu pickling na passivation

3.1 Dị ka ihe ndị a chọrọ nke eserese na akwụkwọ usoro, rụọ acid pickling na passivation tupu ọgwụgwọ na igwe anaghị agba nchara ma ọ bụ akụkụ mgbe emechara.

3. Weld onuete na ịgbado ọkụ slag na abụọ.Hichaa splashes, ma jiri mmanụ ụgbọala ma ọ bụ ihe na-ehicha ihe wepụ ntụpọ mmanụ na unyi ndị ọzọ n'elu akụkụ nhazi akpa.

3.3 Mgbe ị na-ewepụ ihe ndị mba ọzọ n'akụkụ abụọ nke eriri weld, jiri ahịhịa igwe anaghị agba nchara, shọvel igwe anaghị agba nchara ma ọ bụ igwe igwe na-egweri iji wepụ ha, wee kpochaa ha na mmiri dị ọcha (na ọdịnaya ion chloride agaghị agafe 25mg / l).

Mgbe unyi mmanụ siri ike, jiri ngwọta alkaline 3-5% wepụ ntụpọ mmanụ ahụ wee kpochaa ya nke ọma na mmiri dị ọcha.

3. Mechanical ájá ịgbawa nwere ike wepụ oxide akpụkpọ nke igwe anaghị agba nchara na-ekpo ọkụ na-arụ ọrụ akụkụ, na ájá ga-adị ọcha silicon ma ọ bụ aluminum oxide.

3.6 Zụlite usoro nchekwa maka pickling na passivation, ma chọpụta ngwaọrụ ndị dị mkpa na akụrụngwa nchebe ọrụ.

4.Acid pickling, passivation ngwọta na mado usoro

4.1 Usoro ngwọta ịsacha acid: nitric acid (1).42) 20%, hydrofluoric acid 5%, na ndị ọzọ bụ mmiri.Nke dị n'elu bụ pasent olu.

4.2 Acid ihicha ude usoro: 20 milliliters nke hydrochloric acid (ratio 1.19), 100 milliliters mmiri, 30 milliliters nke nitric acid (ratio 1.42), na 150 grams nke bentonite.

4. Usoro ngwọta Passivation: nitric acid (oke 1).42) 5%, Potassium dichromate 4g, nke ọzọ bụ mmiri.Pasent dị n'elu nke ọdịda, okpomọkụ ngafe bụ okpomọkụ ụlọ.

4.4 Passivation tapawa usoro: 30ml nitric acid (ntụkwasị obi 67%), 4g Potassium dichromate, tinye bentonite (100-200 ntupu) na bilie na mado.

5.Acid pickling na passivation ọrụ

5.1 Naanị akpa ma ọ bụ ihe ndị a na-eme pickling na passivation tupu ọgwụgwọ nwere ike ịmalite pickling na passivation.

5. 2 Acid pickling ngwọta bụ tumadi eji maka n'ozuzu ọgwụgwọ nke obere unprocessed akụkụ, na ike fesa.A ga-enyocha okpomọkụ ngwọta kwa nkeji 10 ọ bụla na okpomọkụ nke 21-60 ℃ ruo mgbe etching ọcha na-acha ọcha acid dị.

5.3 Pickling mado Pickling dabara adaba maka nnukwu arịa ma ọ bụ nhazi mpaghara.N'ebe okpomọkụ dị n'ime ụlọ, kpochaa tapawa pickling na akụrụngwa (ihe dị ka 2-3mm), hapụ ya maka otu awa, wee jiri nwayọọ na-eji mmiri ma ọ bụ igwe anaghị agba nchara na-asa ahịhịa ruo mgbe etching ọcha na-acha ọcha na-apụta.

5.4 Passivation ngwọta bụ tumadi adabara n'ozuzu ọgwụgwọ nke obere containers ma ọ bụ components, na ike imikpu ma ọ bụ fesa.Mgbe ihe ngwọta okpomọkụ bụ 48-60 ℃, lelee kwa nkeji 20, na mgbe ngwọta okpomọkụ bụ 21-47 ℃, na-elele kwa awa ruo mgbe a edo passivation film kpụrụ n'elu.

5.5 Passivation mado bụ tumadi adabara nnukwu containers ma ọ bụ mpaghara nhazi.A na-etinye ya nke ọma n'elu akpa pickled (ihe dị ka 2-3mm) na ụlọ okpomọkụ ma nyochaa maka awa 1 ruo mgbe e mepụtara ihe nkiri passivation edo n'elu.

5.6 Acid pickling na passivation containers ma ọ bụ akụkụ ga-eji mmiri dị ọcha sachaa ya., Jiri mpempe ule acidic litmus nwalee akụkụ ọ bụla nke ebe a na-asacha, iji kpochaa elu ya na mmiri pH n'etiti 6.5 na 7.5, wee hichaa ma ọ bụ kpochaa ya na ikuku abịakọrọ.

5.7.Mgbe ịchachara na ngafe, amachibidoro ịcha ihe nkiri passivation mgbe a na-ejizi, na-ebuli ma na-echekwa arịa na akụkụ.

Oge nzipu: Ọgọst-08-2023